www.citrelay.com

phone - 763.535.2339 fax - 763.535.2194

page 28

Technical Data

Temperature & Insulation Class

A variety of applications call for relays which can run at higher temperatures typically caused by high ambient temperatures and/or high contact

switching current, which can lead to field failure.

CIT Relay & Switch offers its J107F, J109F, J114AF, J114FL, J115F, J117F and J123F styles with the higher UL class F (155

°

C) rating as standard;

these relays are often used in high temperature applications including HVAC, industrial, spa & pool, automotive and appliance controls. Selection

of the correct insulating system UL Class A, B or F is essential because it separates the coil (control side of the relay) from the switching side

(contacts) of the relay. Maximum ambient temperatures in the application should be considered to determine the correct UL temperature class se-

lection. UL designed specific test proceedures to insure that field breakdown does not occur from agin and heating and has assigned the ratings in

the table below to approve and describe relays falling into specific catagories. CIT Relay & Switch product has been tested by UL and its tempera-

ture class ratings are included in its UL documentation and catalog specifications. The "Hot Spot" temperature noted in the table relates directly to

coil temperature which is a result of the self-heating temperature. At normal room and office temperatures most coils will not exceed 130

°

C under

full contact load and continuous operation. In higher ambient temperatures it is possible that temperatures will exceed this level in which case the

UL F class 155

°

C relay may be the best solution. For extreme temperatures exceeding 155

°

C, contact CIT Relay & Switch for solutions up to 180

°

C.

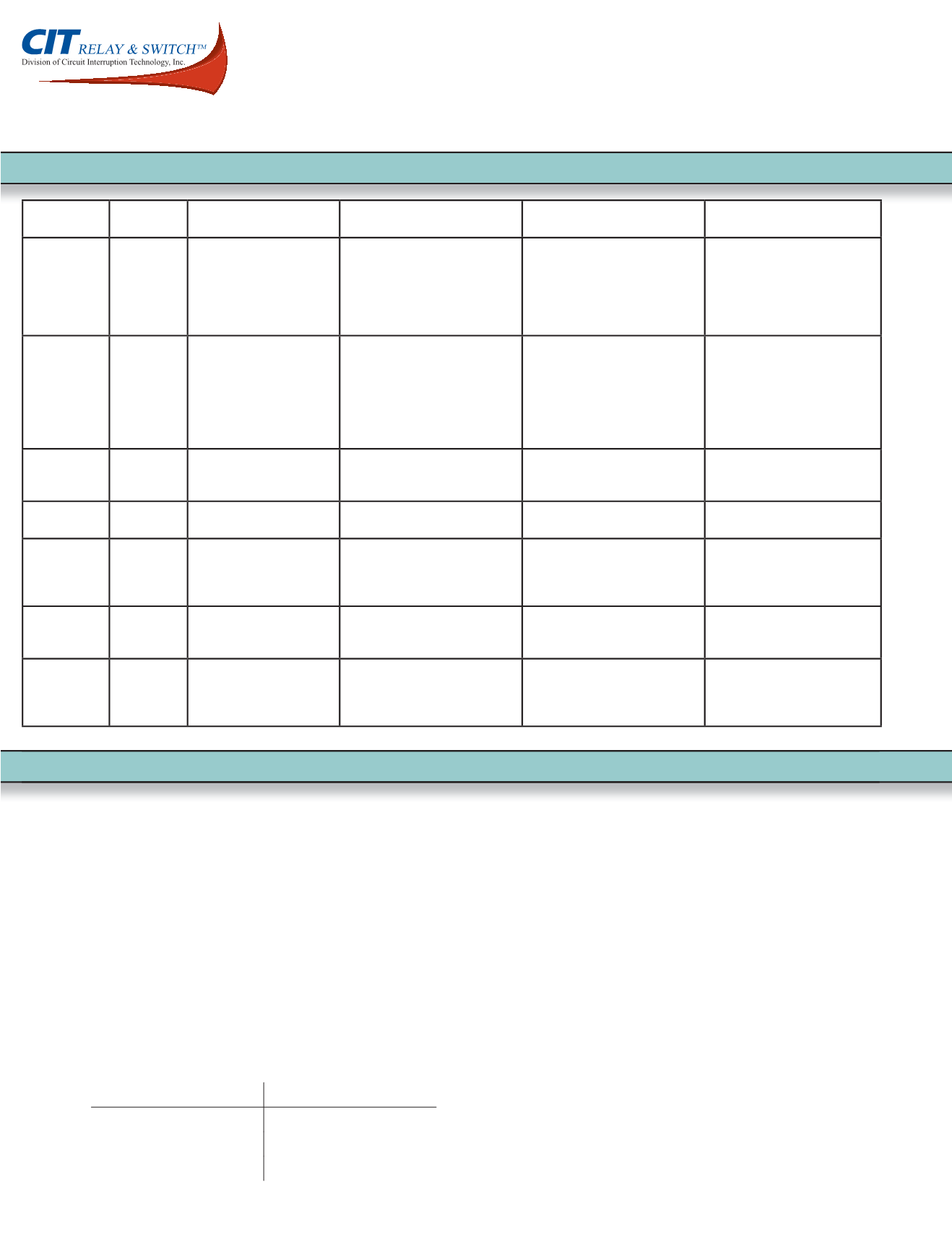

Maximum Hot Spot Temperatures of Insulating Systems**

System Class*

C

°

*Figures derived from UL document 1446

A

105

** Insulation System - Defined as the combination of insulating

materials used in the relay coil inclusive of magnet wire coating

and the outer wrapping of the relay coil

B

130

F

155

Contact

Material

Chemical

Composition

Typical Loads

Recommended

Advantages

Disadvantages

Notes

Gold

Au

Dry Circuit

< 0.4VA

No corrosion forms

Low electrical noise

Poor resistance to metal transfer

with loads greater than 1/2A

Gold clad is often used to block

the polymer buildup. Where gold

plating is used CIT recommends

15 micro inch over a nickle base or

standard silver rivet. All CIT relay

contacts can be gold plated

Silver Paladium AgPd

1 milliamp @ 1 Volt min,

5A maximum

Resistant to sulfidation

Resistant to oxidation

Good contact wear

Good resistance to metal transfer

Low electrical noise level

Life expectancy of 10 times that of

fine silver

Expensive

Low electrical conductivity

Poly buildup in dry circuit condition

Contacts should be bifurcated to

ensure make

Has yet to prove cost effective.

Fine Silver

Ag

10 milliamp @5 Volt min,

10A maximum

High electrical conductivity

High thermal conductivity

Resistant to oxidation

Sulfidation easily forms

Easily welds at higher current levels

High electrical noise

Silver Nickel

AgNi10

10 milliamp @5 Volt min,

40A maximum

Good contact wear

Good resistance to welding

Higher contact resistance

90% Silver, 10% Nickel

Silver Cadmium

Oxide

AgCdO

10 milliamp @5 Volt min,

40A maximum

Good contact wear

Good resistance to welding

Superior resistance to metal loss &

transfer

Environmental concerns

Higher contact resistance

Sulfidation easily forms

Relay manufacturers are phasing

out this material due to RoHS

requirements

Silver Tin Oxide AgSnO

2

100 milliamp @5 Volt min,

50A maximum

High Thermal conductivity

Excellent resistance to welding

High contact resistance

Low electrical conductivity

Sulfidation easily forms

CIT standardizaed contact of choice

Silver Tin Oxide

Idium Oxide

AgSnO

2

In

2

O

2

100 milliamp @5 Volt min,

50A maximum

High thermal conductivity

Excellent resistance to welding

Used with very high inrush loads

High melting point

High contact resistance

Low electrical conductivity

Contact wear

Solfidation easily forms

CIT contact for very severe inrush

loads

Contact Material Review