www.citrelay.com

phone - 763.535.2339 fax - 763.535.2194

page 29

Technical Data

Soldering Guidelines

Guidelines for Soldering

Guidelines for Wave Soldering

CIT Relay & Switch recommends using a no-clean flux during any wave soldering process. The terminal area on most CIT product is epoxy sealed,

thus reducing the incidence of flux wicking into the inner cavity via the terminals. Most switch covers, actuators and bushings are not sealed and

care should be taken to ensure that the product is not immersed or sprayed with flux during the soldering process. Good venting is required during

the wave soldering process. Flux vapors can enter unsealed portions of the product and condense inside of the cavity contaminating the contact

area. If a cleaning process is required, care should be taken to ensure that the product is not immersed or sprayed with any fluids or solutions.

Generally sealed components withstand these issues.* A cooling period between the flow soldering process and board washing with enhance the

outcome.

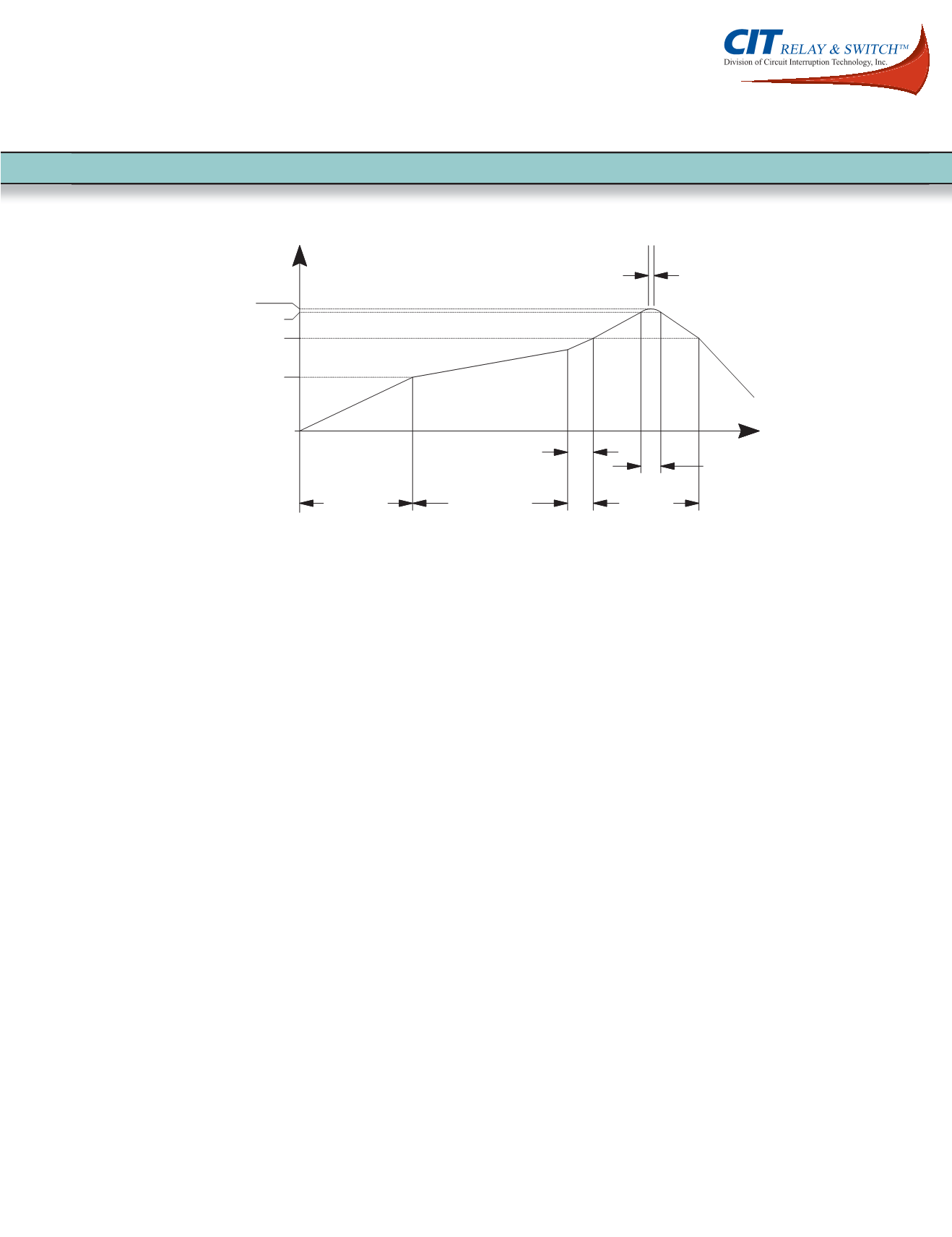

Preheat Temperature & Time

Circumferential temperature of the PC board not to exceed 100

°

C (212

°

F) for 45 seconds

Soldering Temperature & Time

Solder bath temperature not to exceed 260

°

C (482

°

F) for 5 seconds

Guidelines for Hand Soldering

CIT Relay & Switch recommends using a no-clean flux during any hand soldering process. The terminal area on most CIT product is epoxy sealed,

thus preventing flux from wicking into the inner switch cavity via the terminals. The contact path on all insert-molded parts from the inner switch

cavity to the tip of each terminal is irregular in shape to prevent flux migration. However, the covers, actuators and bushings are not sealed and

care should be taken to ensure that the product is not immersed or sprayed with flux during the soldering process. Good venting is required during

the wave soldering process. Flux vapors can enter unsealed portions and condense inside of the cavity contaminating the contact area. If a clean-

ing process is required, care should be taken to ensure that the component is not immersed or sprayed with any fluids or solutions

Hand Soldering Temperature & Time

Recommended soldering irons not to exceed 50W. Solder and iron should contact terminals for maximum of 5 seconds.

* Prior to pre-tinning terminals, flux is applied. Afterwards the terminals are washed prior to the final process of cover installation and epoxy seal

application. Epoxy will not adhere to terminal areas in the rare instance where flux remains present after the wash/cleaning process.

5 ~ 10 s

5 s max Peak Temp.

60 s max

120 ~ 150 s

60 s max

30 s max

TIME

TEMPERATURE

150ºC

230ºC

255ºC

MAX 260ºC

AMBIENT

TEMPERATURE